Case Erectors & Case Sealers

Request a quote

Our case erecting and case sealing solutions are designed to help you achieve efficient, high-quality results. With standard features and tailored options, they’re ideal for businesses seeking optimized packaging performance in industries such as produce and agriculture, dairy, protein, industrial and processed foods.

- Improve packaging precision with reliable case erecting and sealing.

- Reduce labor costs with fully automated processes that require minimal manual intervention.

- Enhance operational efficiency by minimizing downtime through reliable machine performance.

- Adapt to your needs with a wide range of customizable options.

Explore our range of Case Erectors & Case Sealers

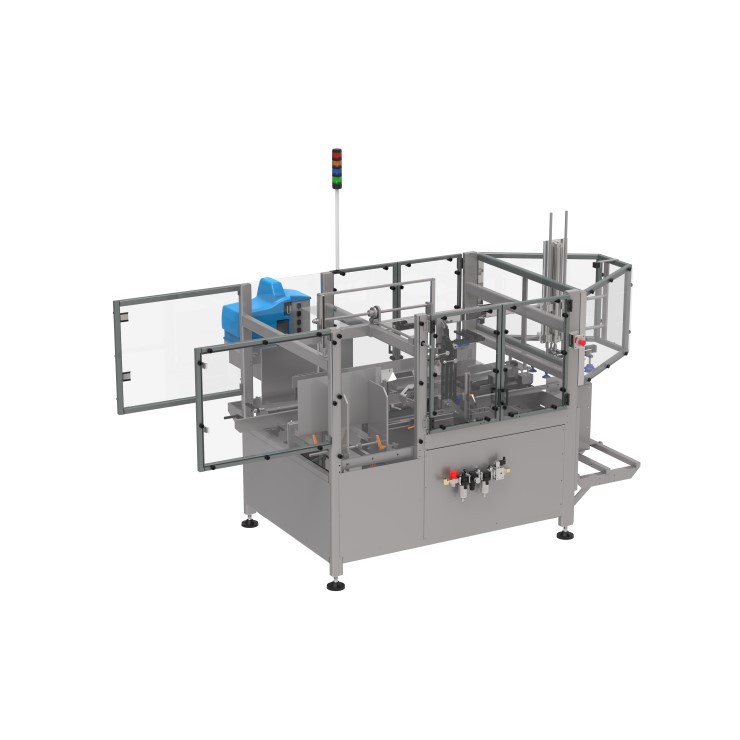

CE1515 Glue Case Erector

The CE1515 Glue Case Erector is a high-speed, fully automatic solution designed to optimize your packaging process with minimal operator supervision. Engineered for versatility and reliability, this machine supports RSC, HSC, and POL box styles, with flexible sealing configurations including FOL Seal and FOL Sandwich/Beverage Seal. It features bottom sealing with hot melt adhesive to ensure a secure closure.

Cases per minute (CPM)

- Up to 20 CPM (standard)

- Up to 35 CPM (with the blank stack containment option)

Erected case size (LxWxD)

- Minimum: 7.00" x 5.00" x 6.50" (177.8mm x 127mm x 165.1mm)

- Maximum: 24.00" x 16.00" x 24.00" (609.6mm x 406.4mm x 609.6mm)

Equipment dimensions

- 153.50” x 85.00” x 87.25” (3.90m x 2.16m x 2.22m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

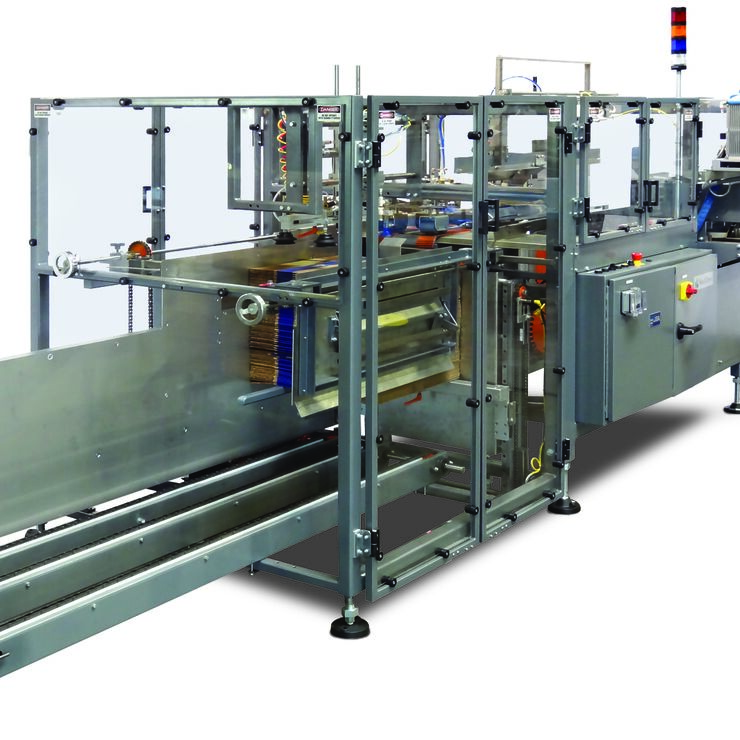

CE1517 Tape Case Erector

The CE1517 Tape Case Erector is a fully automatic solution designed to optimize your packaging process with minimal operator supervision. Built for versatility and reliability, it is engineered to handle RSC and HSC box styles, with customizable options such as FOL Seal (minors–major–major). The standard model bottom seals with 2” pressure-sensitive tape for seal reliability, but it can also be customized to accommodate a wide range of box formats and 3” tape.

Cases per minute (CPM):

- Up to 20 CPM with 2” tape

- Up to 25 CPM with 2” tape (with blank stack containment options) or 3” tape (with a 3” high-speed tape head)

Erected case size (LxWxD)

- Minimum: 7.00" x 5.00" x 6.50" (177.8mm x 127mm x 165.1mm)

- Maximum: 24.00" x 16.00" x 24.00" (609.6mm x 406.4mm x 609.6mm)

Equipment dimensions

- 153.00” x 83.00” x 86.25” (approx.); (3.89m x 2.11m x 2.17m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

CRCE - Continuous Running Case Erector

The Continuous Running Case Erector is a high-speed, fully automatic solution that applies a glue adhesive and is designed to optimize your packaging process with minimal operator supervision. The Continuous Running Case Erector is a high-speed, fully automatic solution that applies a glue adhesive and is designed to optimize your packaging process with minimal operator supervision. Built for versatility and reliability, this model supports RSC, HSC, and POL box styles with customizable FOL and Sandwich/Beverage sealing options. It features bottom glue sealing and continuous case feeding for high-efficiency operation.

Cases per minute (CPM)

- Up to 35 CPM

Erected Case Size (LxWxD)

- Minimum: 7.00" x 5.00" x 6.50" (177.8mm x 127mm x 165.1mm)

- Maximum: 25.00" x 16.00" x 24.00" (635mm x 406.4mm x 609.6mm)

Equipment dimensions

- 207.5” x 84.75” x 91.375” (5.27m x 2.15m x 2.32m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1023 Top-Bottom Case Sealer

The TS1023 Top-Bottom Case Sealer is a high-performance solution designed for reliable and efficient sealing operations. Built with robust welded carbon steel, it features an ergonomic design to improve workflow and can seal cases at up to 30 CPM. Compatible with RSC, HSC, and POL box styles, it offers flexibility with both glue and tape adhesive options.

Cases per minute (CPM)

- Up to 30 CPM

Erected case size (LxWxD)

- Minimum: 6.00" x 4.00" x 4.50" (152.4mm x 101.6mm x 114.3mm)

- Maximum: 24.00" x 18.00" x 20.00" (609.6mm x 457.2mm x 508mm)

Equipment dimensions

- 121.50” x 51.50” x 90.00” (3.07m x 1.31m x 2.29m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1052 Top-Bottom Case Sealer

The TS1052 Top-Bottom Case Sealer is engineered for reliable, high-efficiency performance. Capable of sealing up to 40 cases per minute, it enhances productivity without compromising quality. Built for versatility, it supports glue adhesive application and is compatible with RSC, HSC, and POL box styles.

Cases per minute (CPM)

- Up to 40 CPM

Erected case size (LxWxD)

- Minimum: 7.0" x 5.0" x 4.5" (177.8mm x 127.0mm x 114.3mm

- Maximum: 24.0" x 16.0" x 18.0" (609.6mm x 406.4mm x 457.2mm)

Equipment dimensions

- 21.50” x 47.00” x 90.00” (3.09m x 1.19m x 2.29m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1023 Case Top-Sealer

Engineered for consistent, high-performance operation, the TS1023 Case Top-Sealer combines durability with efficiency. Its heavy-duty welded carbon steel frame and ergonomic design streamline workflows and simplify maintenance. Capable of sealing up to 30 cases per minute, it supports RSC, HSC, and POL box styles and offers flexibility with both glue and tape adhesive options.

Cases per minute (CPM)

- Up to 30 CPM

Erected case size (LxWxD)

- Min: 6.00” x 4.00” x 4.50” (0.15m x 0.10m x 0.11m)

- Max: 24.00” x 18.00” x 20.00” (0.61m x 0.46m x 0.51m)

Equipment dimensions

- 121.50” x 51.50” x 90.00” (3.09m x 1.31m x 2.29m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1052 Case Top-Sealer

The TS1052 delivers high-performance top sealing with precision and reliability. Designed with a heavy-duty welded carbon steel frame and ergonomic features, it streamlines workflows and enhances operational productivity. Supporting RSC, HSC, and POL box styles, it efficiently seals up to 40 cases per minute using hot melt adhesive for secure and consistent closure.

Cases per minute (CPM)

- Up to 40 CPM

Erected Case Size (LxWxD)

- Minimum: 7.0" x 5.0" x 4.5" (177.8mm x 127mm x 114.3mm)

- Maximum: 24.0" x 16.0" x 18.0" (609.6mm x 406.4mm x 457.2mm)

Equipment dimensions

- 121.50” x 47.00” x 90.00” (3.09m x 1.19m x 2.29m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1130 Case Top-Sealer

The TS1130 Case Top-Sealer delivers high-speed, reliable performance for consistent and precise case sealing, boosting operational efficiency. Engineered with heavy-duty welded carbon steel and an ergonomic design, it enhances durability, streamlines workflows, and simplifies jam clearance. Capable of sealing up to 50 RSC cases or 30 FOL cases per minute, the TS1130 offers flexible adhesive options—glue or tape—to meet diverse packaging needs.

Cases per minute (CPM)

- Up to 50 CPM (RSC)

- Up to 30 CPM (FOL)

Erected Case Size (LxWxD)

- Minimum: 8.0" x 5.0" x 4.0" (203.2mm x 127.0mm x 101.6mm)

- Maximum: 24.0" x 16.0" x 18.0" (609.6mm x 406.4mm x 457.2mm)

Equipment dimensions:

- 162.25” x 51.25” x 79.50” (4.12m x 1.30m x 2.02m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

TS1130 Side Flange Case Sealer

The Side Flange Case Sealer delivers reliability and precision, ensuring streamlined case sealing operations at sealing speeds of up to 30 cases per minute with hot melt adhesive for secure closure. Its robust construction, ergonomic design, and efficient workflow capabilities make it a durable and dependable solution for demanding applications.

Cases per minute (CPM)

- Up to 30 CPM

Erected Case Size (LxWxD)

- Minimum: 12.0" x 8.0" x 4.5" (304.8mm x 203.2mm x 114.3mm)

- Maximum: 24.0" x 16.0" x 12.0" (609.6mm x 406.4mm x 304.8mm)

Equipment dimensions

- 105.75” x 77.25” x 97.00” (2.69m x 1.96m x 2.46m)

Voltage

- 220/230/240 Volts, 3 Phase, 60 Hz (WYE Configuration)

Case Erectors & Case Sealers FAQs

- Our case erecting and sealing machines are compatible with a wide variety of box formats, including RSC, HSC, POL. We also offer customizable options for FOL seals or beverage seals. This versatility ensures suitability for diverse packaging needs across multiple industries.

- Our equipment is designed for automation, reducing manual intervention and improving workflow efficiency. With high-speed capabilities and reliable performance, businesses can achieve significant productivity gains while minimizing downtime.

- Yes, both our case erectors and case closers offer extensive customization options. From box sizes and styles to adhesive applications (tape or glue), many of our machines can be tailored to specific operational needs, ensuring optimal performance.

- Our solutions serve a wide range of industries, including produce and agriculture, dairy, protein processing, industrial goods and processed foods. The adaptability of our equipment makes it ideal for various packaging environments.

- We prioritize reliability and ease of use in our designs, which feature user-friendly components and robust construction. Additionally, we provide comprehensive support and optional service packages to ensure long-term performance and minimal disruptions.

Get in touch

* Mandatory Field