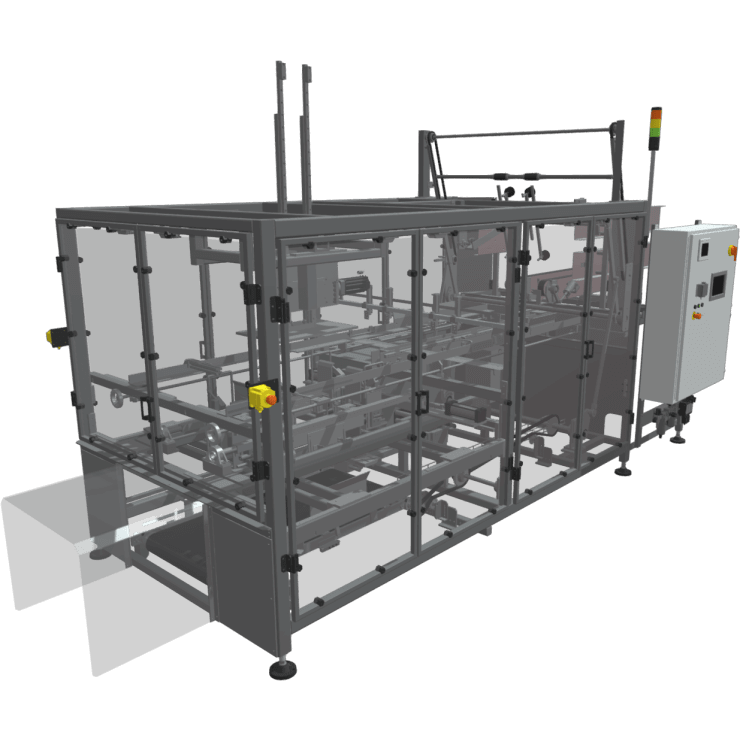

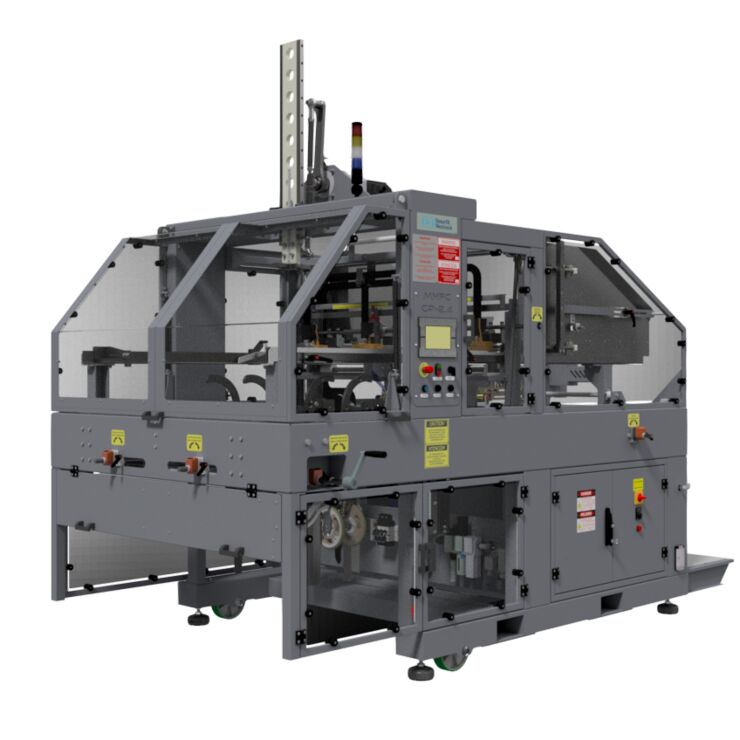

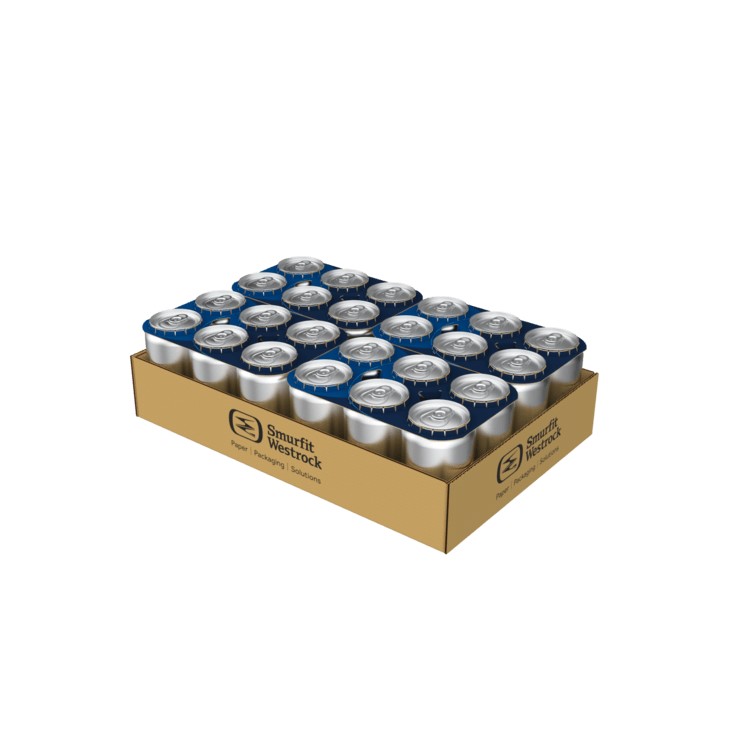

Tray Erectors & Tray Formers

Request a quote

At Smurfit Westrock, we specialize in empowering businesses with tray-forming solutions that drive efficiency, reduce labor and optimize supply chains. Our tray formers are expertly designed to meet the diverse packaging needs of industries such as produce, protein, beverage and processed foods. From standard features to customizable flexibility, our tray formers make it simple to get your products on the shelf fast and into the customers’ shopping carts.

Our tray formers help you:

- Enhance operational efficiency with streamlined automation.

- Reduce manual labor through precise, reliable functionality.

- Adapt seamlessly with versatile options for varying tray dimensions.

- Support sustainability goals by optimizing material usage.

Explore Our Portfolio of Tray Erectors & Tray Formers

Tray Erectors and Tray Formers FAQs

Get in touch

* Mandatory Field