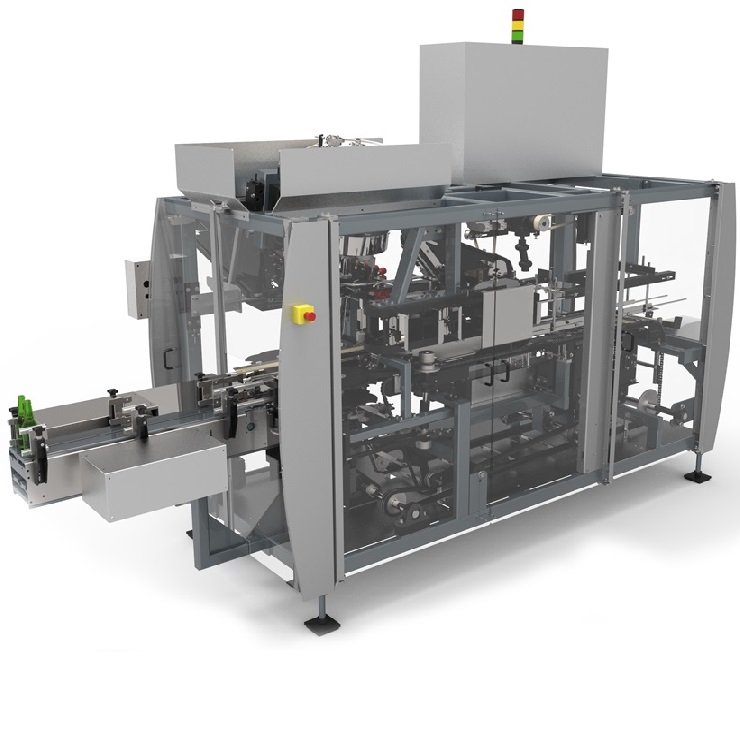

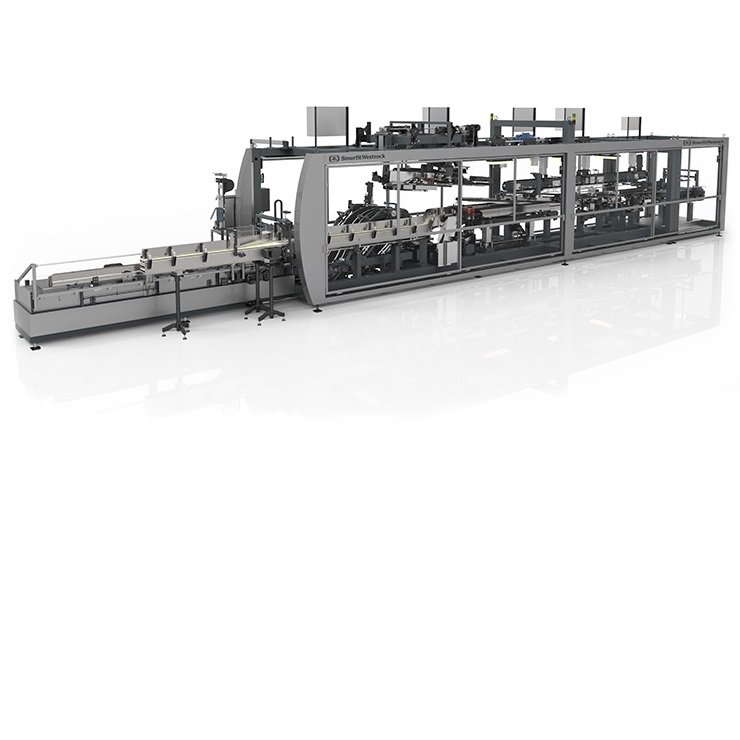

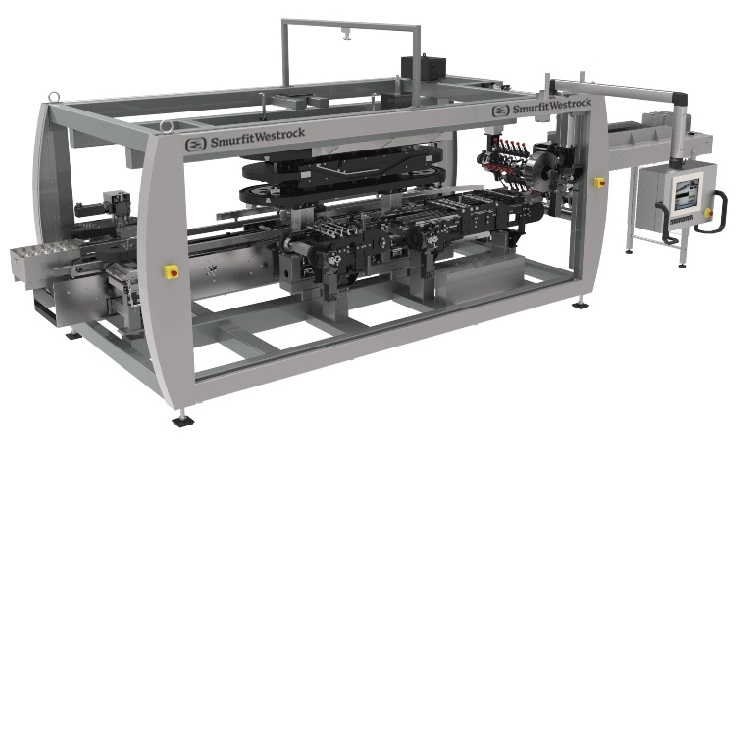

Bottle Multipack Machinery

Request a quote

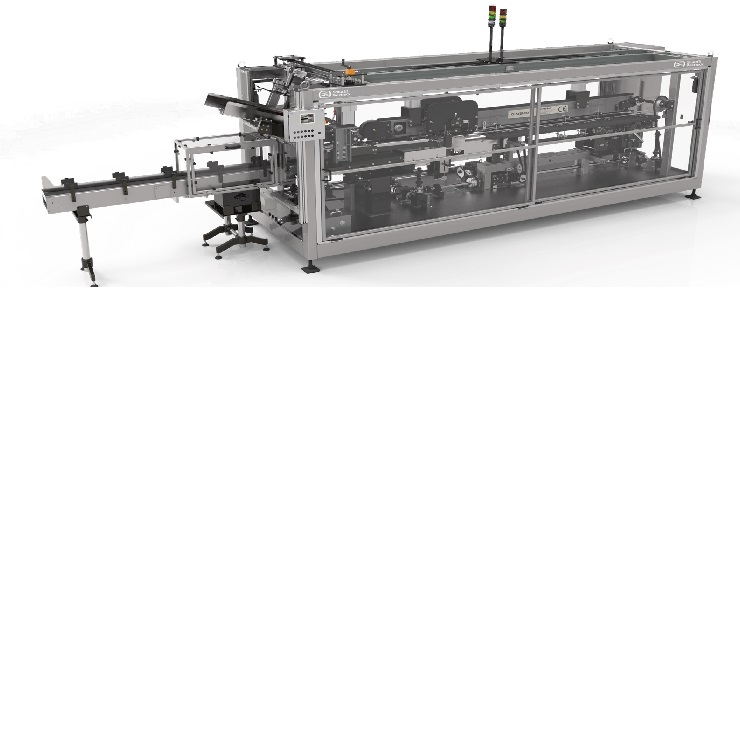

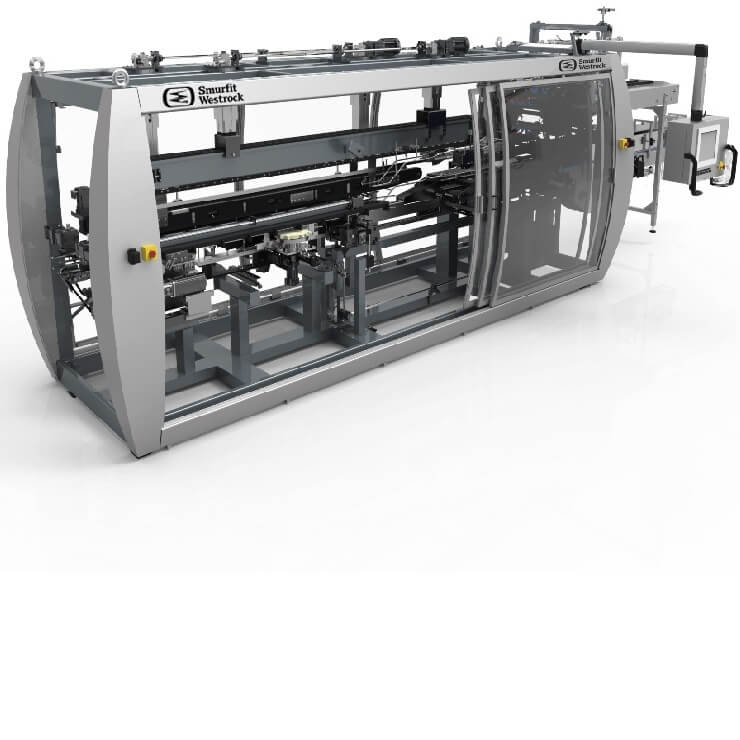

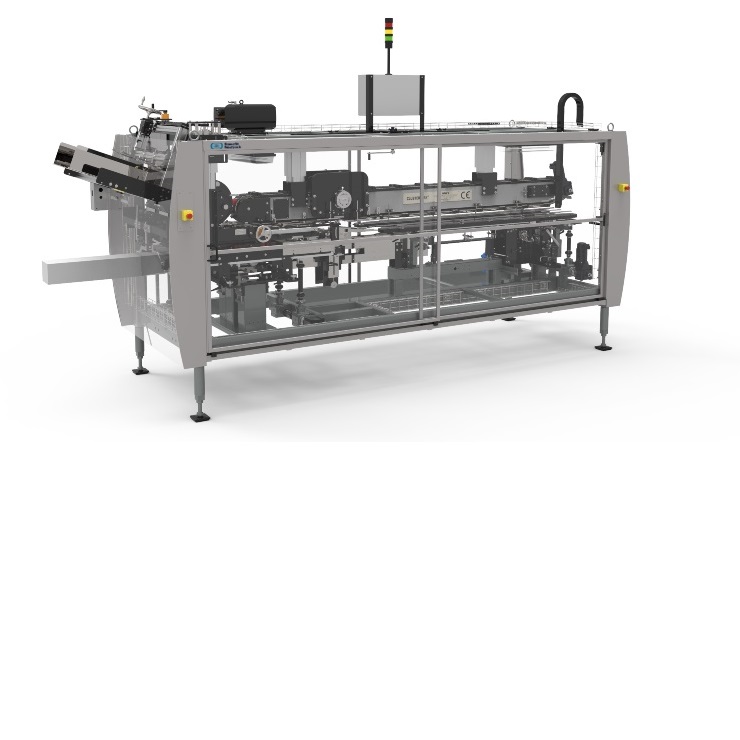

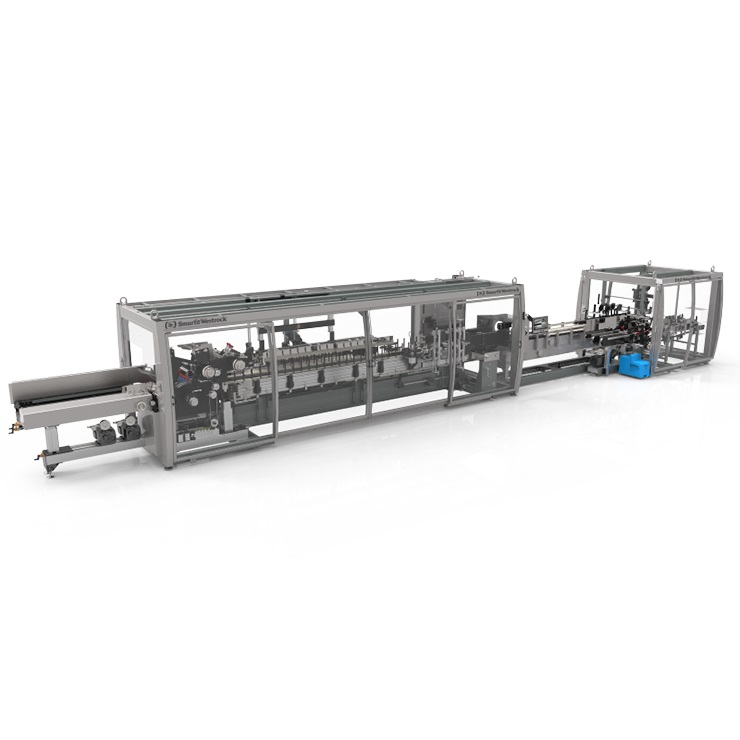

Our bottle multipack machinery is purpose-built to help you scale your beverage packaging solutions while maximizing operational efficiency. Developed by our in-house engineering experts, these advanced automation systems and packaging technologies are designed to work seamlessly together—optimizing your bottling line and supporting your sustainability goals with precision and reliability. With options for PET, glass and aluminium bottles, our comprehensive portfolio of bottle multipack packaging solutions can help you reduce the use of plastic packaging, reallocate essential labor, and meet evolving trends and preferences — all while making an impact on the shelf.

Our bottle multipack machinery can help you achieve:

Operational efficiency

Increase throughput and optimize your beverage packaging line with automated, high-speed paper-based multipack solutions tailored for bottles.

Adaptable and scalable design

Flexible machinery platforms accommodate a wide variety of bottle shapes and sizes, easily adapting to evolving market and production needs.

Labor and cost savings

Reduce manual labor demands and reallocate your workforce by leveraging automation that seamlessly integrates with upstream equipment.

Sustainability

Engineered to support paper-based packaging, our solutions help brands meet sustainability objectives using renewable materials.

Explore Our Bottle Packaging Machinery

Get in touch

* Mandatory Field

Component "CH Related Products" has no content