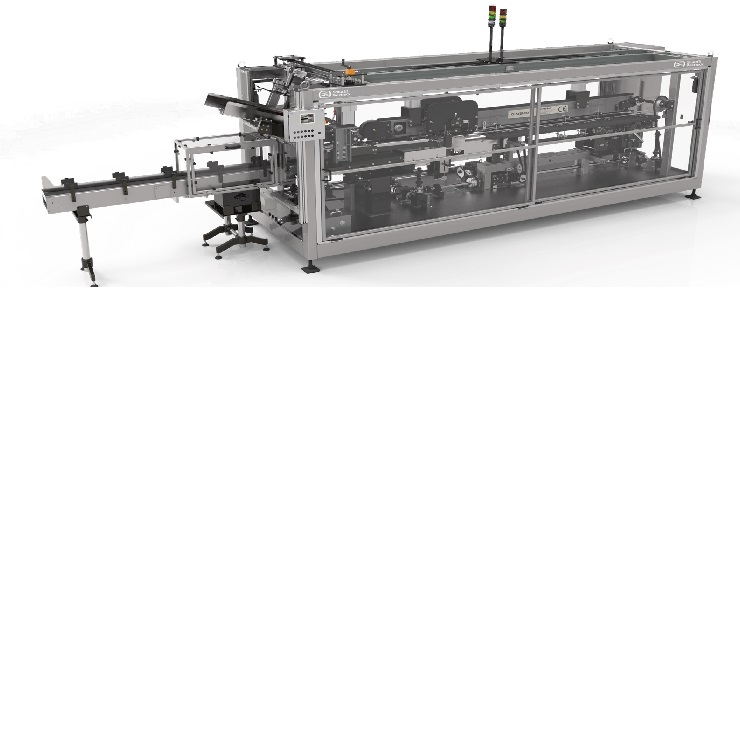

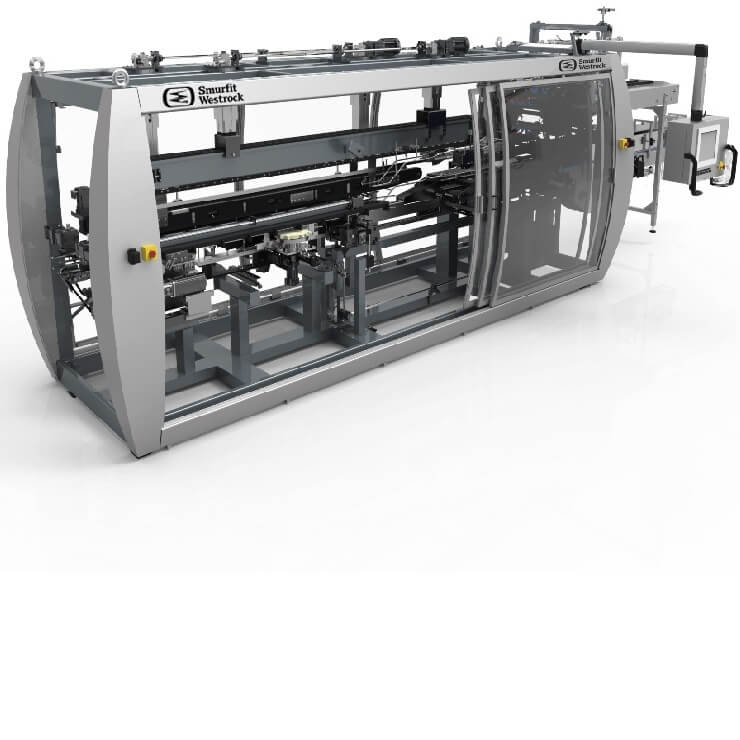

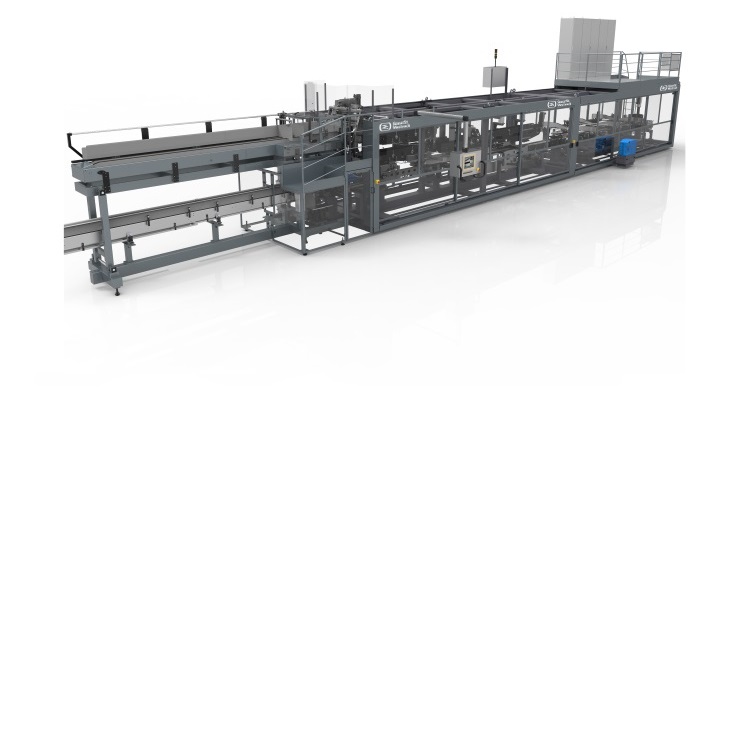

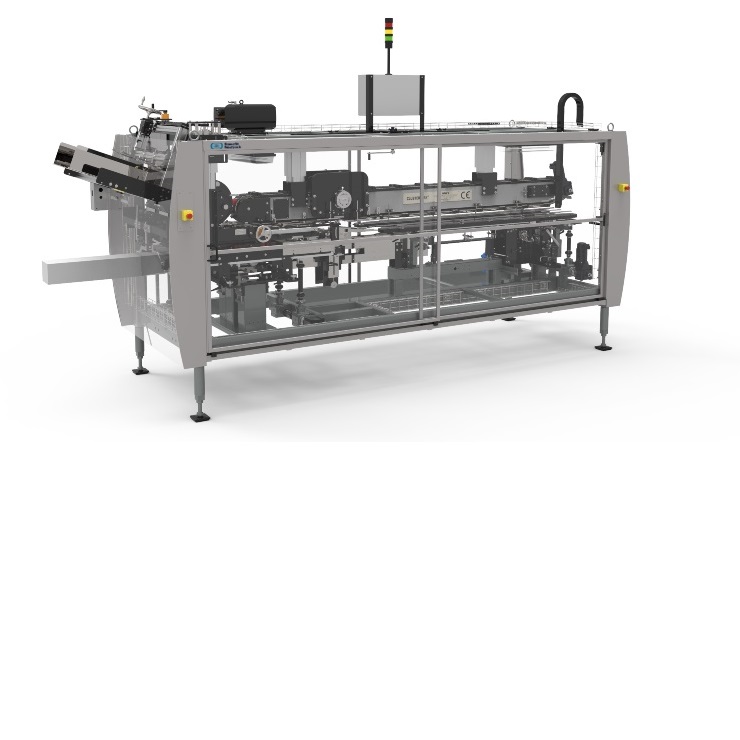

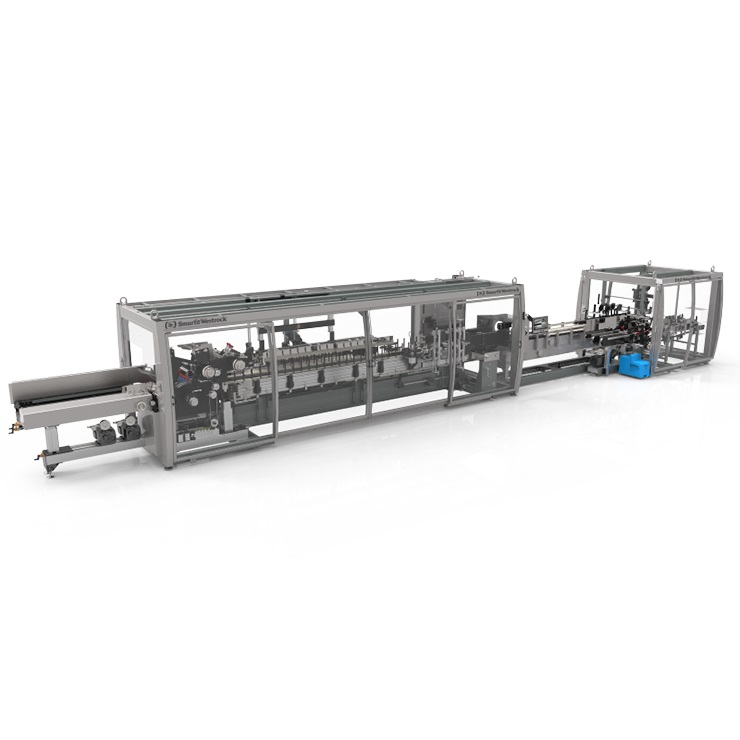

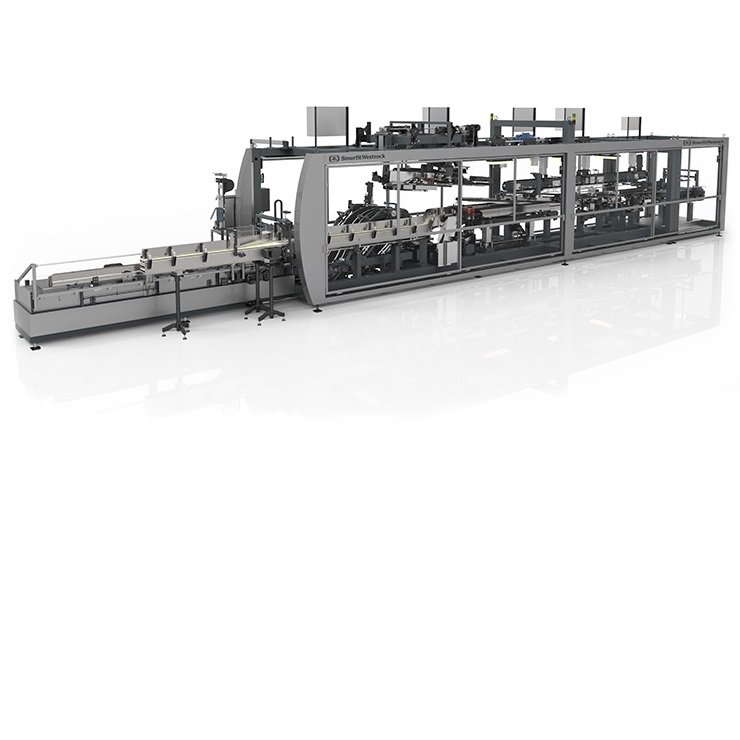

Can Multipack Machinery

Request a quote

Whether you need multipack automation for food or beverage cans, our industry-leading solutions deliver automated, paper-based packaging designed to minimize manual labor and maximize uptime, while seamlessly integrating with your existing line. Engineered for flexibility, our machinery adapts to a wide variety of container types and evolving market needs. With our can multipack automation solutions, you can expect:

Operational Efficiency

Increase throughput and line efficiency with automation designed to minimize manual intervention and maximize uptime.

Labor Optimization

Reduce manual labor needs and enable strategic reallocation of workforce by streamlining multipack packaging operations.

Sustainability

Meet sustainability goals with innovative paper-based packaging solutions leveraging renewable materials.

Unmatched Flexibility

Adapt quickly to changing market demands with machinery engineered to handle a wide variety of primary containers and packaging formats.

Explore Our Can Packaging Machinery

Get in touch

* Mandatory Field

Component "CH Related Products" has no content