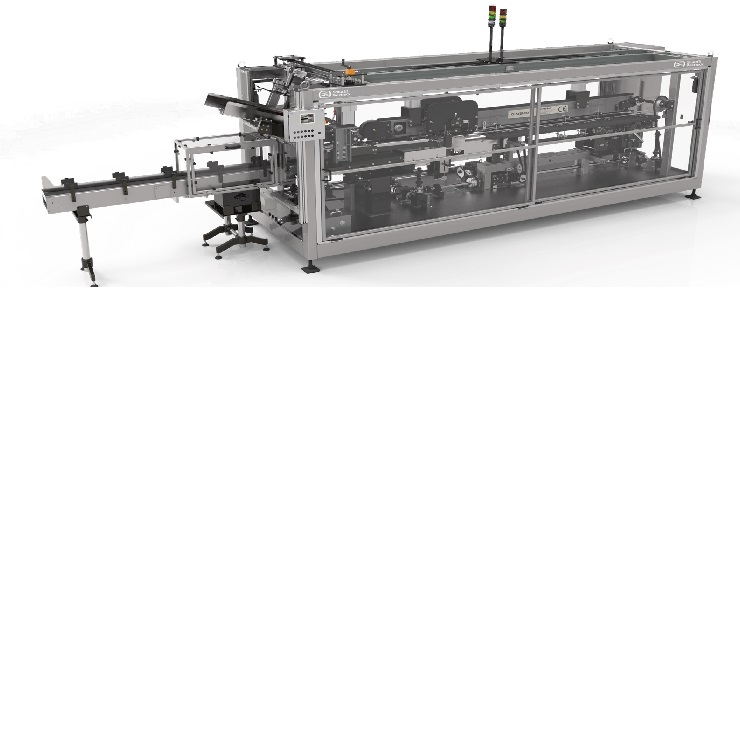

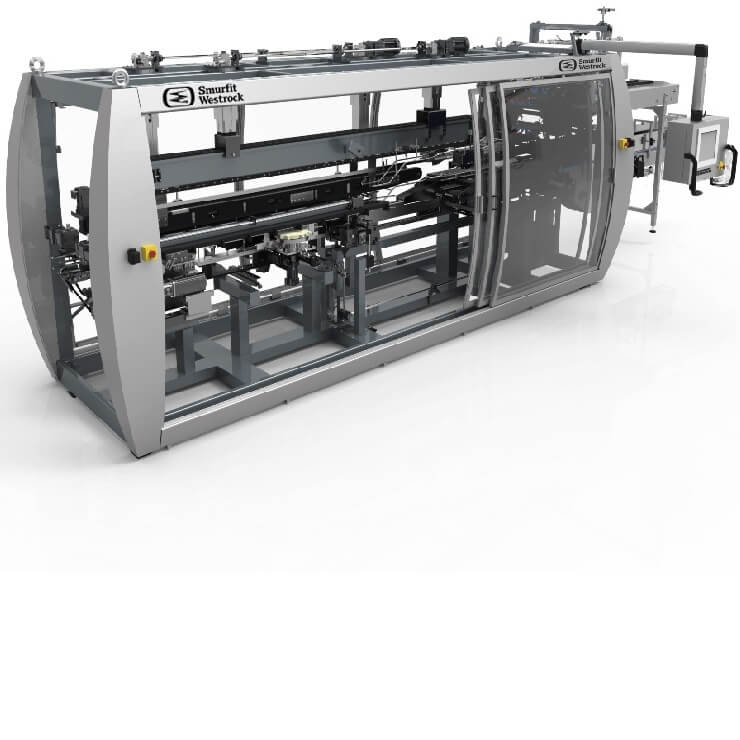

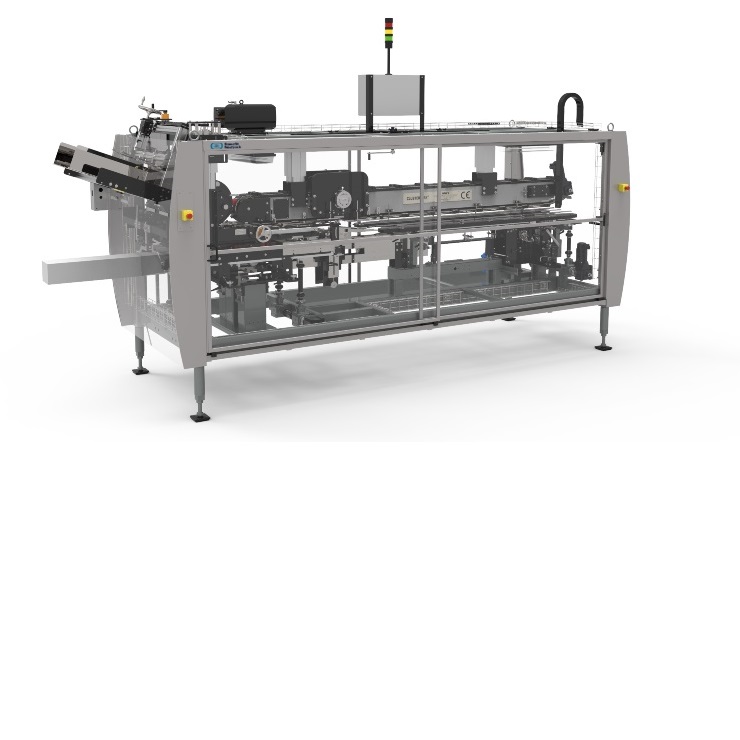

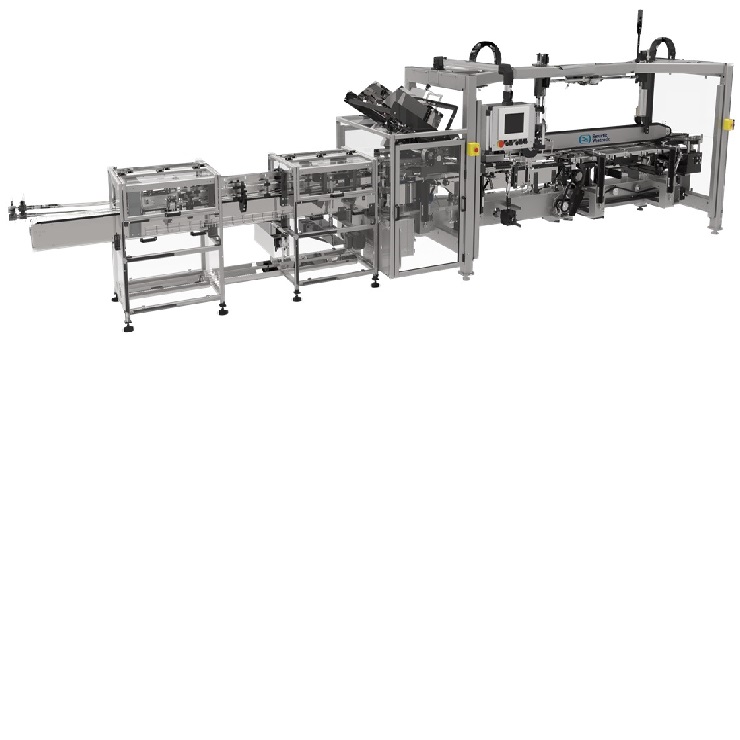

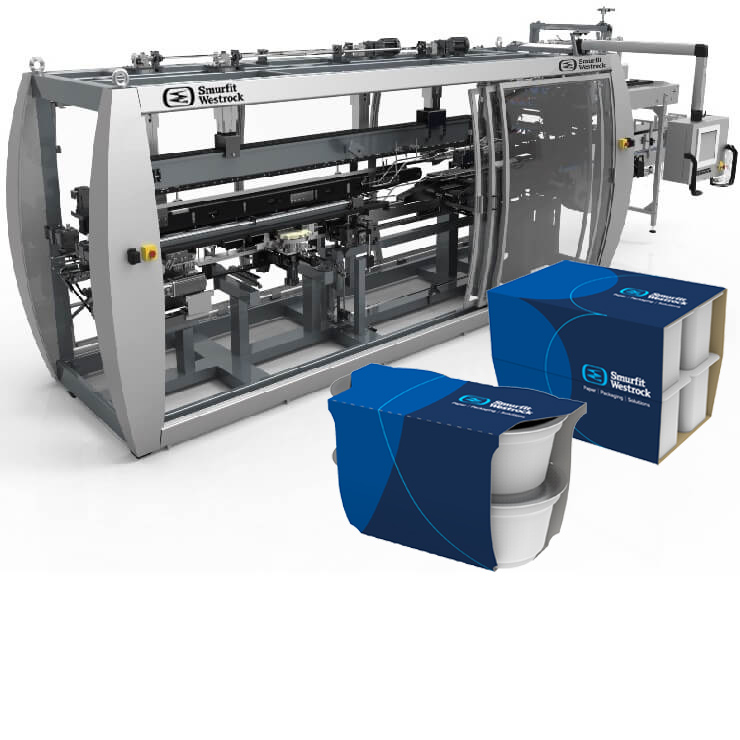

Multipack Sleeve Applicators

Request a quote

Our multipack sleeve applicator portfolio offers scalable, efficient solutions for packaging cups, tubs, bowls, bricks, and more. Precision-engineered machinery ensures seamless integration into your production line, optimizing throughput while reducing manual labor. Versatile and sustainable, our applicators support a wide range of paper-based packaging formats to help you meet evolving market demands.

Our multipack sleeve applicators can help you achieve:

- Operational Efficiency: Automate your multipack packaging process to maximize throughput, reduce manual labor, and minimize downtime across cups, tubs, bowls, and a variety of container types.

- Sustainability: Meet sustainability goals with paper-based packaging solutions integrated seamlessly with high-performance machinery.

- Market adaptability: Flexible machinery platforms are designed to accommodate evolving consumer and industry requirements, optimizing packaging for cups, pots, tubs, bowls and aseptic containers with ease.

Explore Our Packaging Machinery for Cups, Pots, Tubs, Bowls & Aseptic Cartons

Real Results: How Our Customers Succeed With This Product

Get in touch

* Mandatory Field

Component "CH Related Products" has no content